The HIMA F6215 plays a vital role in safety-instrumented systems across industries like oil and gas, chemical processing, and power generation. When these critical components fail, operations can grind to a halt, making access to reliable spare parts essential for minimizing downtime and maintaining safety compliance. However, maintenance teams frequently encounter significant obstacles when sourcing these specialized components. Availability remains unpredictable due to the niche nature of HIMA products, while distinguishing authentic parts from counterfeit alternatives poses serious risks to system integrity. Extended lead times from conventional suppliers can leave facilities vulnerable to prolonged outages, and the costs associated with emergency procurement often strain maintenance budgets. Both original equipment manufacturer (OEM) parts and carefully vetted surplus components offer viable solutions for different operational scenarios. This article guides procurement professionals and maintenance engineers through the landscape of trustworthy HIMA F6215 spare parts sources, helping you make informed decisions that balance quality assurance, availability, and cost-effectiveness while ensuring your critical control systems remain operational and compliant with safety standards.

Understanding HIMA F6215 Spare Parts

The HIMA F6215 serves as a digital output module within HIMax safety systems, converting electronic signals into physical switching actions that control valves, pumps, and other field devices in safety-critical applications. This module executes shutdown commands and manages process control functions where failure could result in hazardous conditions or environmental incidents. Its robust design enables reliable operation in demanding industrial environments, but like all electronic components, it experiences wear over time.

Common replacement components for the F6215 system include the output modules themselves, which handle the primary switching functions, along with connection terminals that facilitate field wiring. Power supply units that energize the modules require periodic replacement, while communication cards that enable system integration may fail due to electrical surges. Backplane connectors, status indicator LEDs, and protective fuses also appear frequently on maintenance parts lists. Understanding which specific component has failed determines the appropriate replacement strategy.

When sourcing replacements, you'll encounter three distinct categories. OEM parts come directly from HIMA's manufacturing pipeline with full documentation, warranties, and guaranteed compatibility with existing firmware versions. Surplus parts represent unused inventory from discontinued projects or excess stock from other facilities—these authentic HIMA components offer significant cost savings but may lack warranties or updated firmware. Aftermarket parts, manufactured by third parties, attempt to replicate OEM specifications but introduce compatibility uncertainties and potential safety compliance issues that make them unsuitable for critical safety systems where certification requirements demand documented traceability.

Key Challenges in Sourcing HIMA Spare Parts

The specialized nature of HIMA F6215 components creates significant availability constraints that maintenance teams struggle to navigate. Unlike commodity industrial parts with multiple manufacturers, HIMA's proprietary safety systems serve a limited market segment, resulting in fewer distributors maintaining inventory. Many facilities discover their preferred suppliers stock only fast-moving items, leaving critical F6215 modules available only through special order with frustratingly long fulfillment windows that can extend from weeks to months.

Counterfeit components present an escalating threat in the industrial automation sector. Unscrupulous vendors exploit the high demand and limited supply by offering remarkably similar-looking parts that lack proper safety certifications and fail to meet HIMA's rigorous performance standards. These substandard alternatives may function initially but degrade rapidly under operational stress, potentially compromising entire safety systems. The consequences extend beyond equipment failure to include invalidated safety certifications and liability exposure during incident investigations.

Lead time unpredictability compounds operational planning difficulties. Traditional procurement channels through authorized distributors often require extensive processing periods, particularly for components requiring factory configuration or firmware updates. Emergency situations force maintenance teams into reactive purchasing at premium rates, sometimes paying double or triple standard costs for expedited delivery. Budget constraints become particularly acute when unplanned failures demand immediate replacement, creating tension between financial limitations and operational necessity while management seeks cost-effective solutions that don't compromise system reliability or safety compliance requirements.

Top Sources for Reliable HIMA F6215 Parts

Authorized HIMA Distributors

Purchasing through authorized HIMA distributors provides the highest assurance of authenticity and performance. These official channels supply factory-certified components with complete documentation, including certificates of conformity and traceability records essential for safety audits. OEM parts come with manufacturer warranties that protect against defects and ensure compatibility with your existing system configuration, eliminating concerns about firmware mismatches or integration failures. To verify a distributor's authorization status, visit HIMA's official website and check their partner directory, or contact HIMA directly to confirm a supplier's credentials before placing orders. Request written proof of authorization and examine invoices carefully to ensure they reference HIMA as the manufacturer rather than vague descriptions that might indicate third-party sourcing.

Trusted Surplus Parts Suppliers

Reputable surplus suppliers offer genuine HIMA components at reduced prices, typically ranging from 30-60% below OEM rates. These parts originate from decommissioned facilities, canceled projects, or distributor overstock rather than counterfeit operations. Quality surplus vendors test components before sale, provide detailed condition reports, and offer limited warranties that demonstrate confidence in their inventory. However, exercise caution by requesting serial number verification, examining packaging for signs of tampering or deterioration, and asking for documentation proving the part's origin. Avoid suppliers who cannot provide clear answers about component history, offer prices that seem unrealistically low compared to market rates, refuse to share testing procedures, or hesitate to provide references from previous industrial customers.

Online Marketplaces with Verification

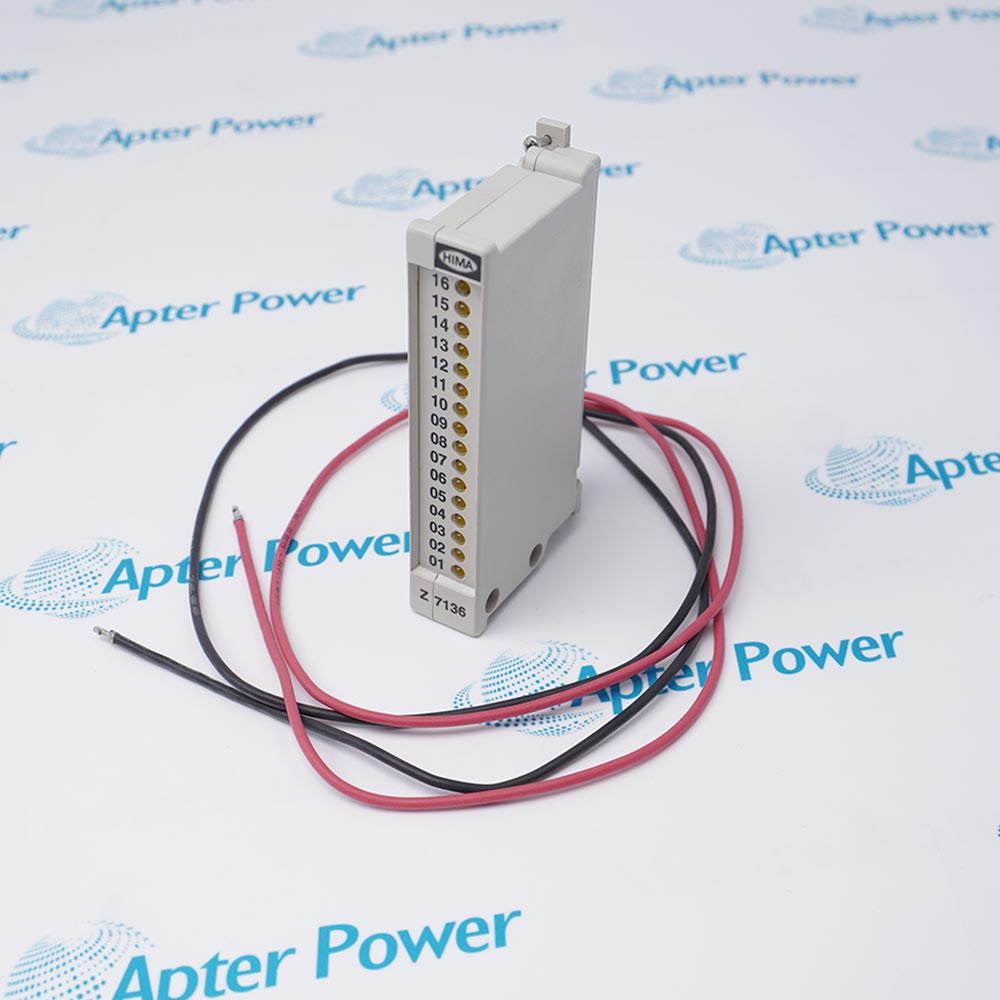

Specialized industrial automation platforms connect buyers with verified sellers who maintain inventory specifically for control system components. These marketplaces implement seller vetting processes that include business verification, transaction history reviews, and customer feedback systems that help identify reliable vendors. Suppliers like Apter Power, which specialize in automation and industrial spare parts, often maintain inventory of critical safety system components alongside comprehensive testing documentation. Look for platforms that require sellers to provide detailed part specifications, including manufacturing dates, condition assessments, and high-resolution photographs showing serial numbers and physical condition. Prioritize sellers with established ratings above 95%, substantial transaction histories demonstrating consistent performance, and responsive communication patterns. Always verify that listings include complete part numbers matching your exact requirements, and request additional documentation such as test reports or origin certificates before finalizing purchases, particularly for higher-value modules where authenticity verification justifies the extra diligence.

Evaluating HIMA Spare Parts Suppliers

Establishing a systematic evaluation framework protects your facility from unreliable vendors and substandard components. Begin by requesting ISO 9001 quality management certifications that demonstrate commitment to consistent processes, along with any industry-specific accreditations relevant to safety instrumented systems. Ask suppliers to provide documentation of their testing procedures—reputable vendors perform functional testing on modules, verify communication protocols, and conduct visual inspections for physical damage or corrosion before listing parts for sale.

Direct your inquiries toward concrete operational details that reveal supplier capabilities. Specifically ask how quickly they can confirm stock availability for your exact part number, what their typical lead times are for in-stock versus special-order items, and whether they maintain safety stock for critical F6215 components. Request information about their packaging methods to ensure proper protection during shipping, and inquire about their supply chain transparency, including whether they can trace component origins and provide manufacturing date codes that help you assess remaining service life.

Return policies and technical support separate professional suppliers from opportunistic resellers. Insist on clear return windows that allow adequate time for receiving inspection and compatibility testing—minimum 30-day return periods indicate supplier confidence in their inventory quality. Evaluate their technical resources by asking whether they employ staff familiar with HIMA systems who can answer configuration questions, provide installation guidance, or troubleshoot compatibility concerns. Suppliers offering post-sale support, including assistance with firmware verification and system integration questions, demonstrate genuine commitment to customer success beyond the initial transaction, making them valuable long-term partners for your maintenance operations.

Making Informed Procurement Decisions

Sourcing reliable HIMA F6215 spare parts requires balancing three critical factors: quality assurance, availability, and cost-effectiveness. Authorized HIMA distributors provide the highest certainty with factory-certified components, complete documentation, and manufacturer warranties, making them ideal for facilities where compliance and traceability are non-negotiable. Trusted surplus suppliers offer genuine parts at substantially reduced prices for budget-conscious operations willing to accept limited warranties in exchange for significant savings. Online marketplaces with robust verification systems bridge these options by connecting you with diverse sellers while providing transparency through ratings and detailed listings. Regardless of which source you choose, implement rigorous supplier evaluation practices that include certification verification, testing documentation review, and clear communication about lead times and return policies. Developing relationships with multiple reliable suppliers creates supply chain resilience that protects against future disruptions. Before finalizing any purchase, always double-check part numbers against your system documentation, verify serial numbers match authentic HIMA formatting, and confirm compatibility with your existing firmware version. This proactive approach to spare parts procurement minimizes downtime, maintains safety system integrity, and ensures your critical control infrastructure remains operational when it matters most.